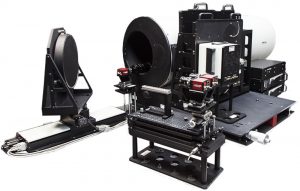

SBIR offers various ranging test bench systems that can be configured for non-infinity focus testing. Each system can be specifically designed for various tasks including characterizing the performance of IR and visible sensors and performing multi-sensor boresighting (IR to Visible to Laser).

The design of these test benches is similar to many other test systems that SBIR has manufactured. Each system includes a broadband collimator, precision differential blackbody, uniform large area visible source, multi-position motorized target wheel and either a manual micrometer driven range simulation platform or an automated non-infinity focus adjustable range simulation platform.

Broadband, reflective off-axis Newtonian collimators

Precision visible and infrared sources

iProbe temperature sensors

Multi-position target wheels

2 year warranty

Adjustable focus platform for testing at specific distances (non-infinity focus)

Available with manual or automated source (blackbody, visible source, laser source etc.) select slides

Camera based boresight alignment module for co-aligning different sensors

Laser beam profiling and analysis modules

Filter wheels for attenuating specific wavelengths of interest

16 or 32 position target wheels available

AZ/EL adjustment stages for specific UUTs

IRWindows™5 automated test software

Below is a list of some recent ranging systems. If you would like more information about one of the items listed please contact the SBIR sales team at 805-965-3669 or sales@sbir.com.

Model 13495 is one of a series of turn-key test systems offered by Santa Barbara Infrared. The system is designed for laboratory and production characterization and testing of modern EO instruments including thermal imagers, day sights, image intensified sensors, and direct-view optical systems. Optional modules for testing of laser rangefinders, designators, illuminators and spot trackers can be added for complete testing of currently fielded military multi-sensor pods and gimbals. Testing is automated, using the SBIR IRWindows™ system control and test platform. The Model 13495 includes an all-reflective broadband collimator, target wheel, filter wheel, range simulation stage, differential blackbody, Vis/NIR/SWIR source, and IRWindows™ . An AZ/EL stage assembly mount that interfaces to TPS fixtures for each UUT is mounted in front of the collimator, locating the UUT in collimated space. A CCD camera mounts behind the UUT and is used to view the display in the eyepiece of the UUT. Images from the CCD camera are utilized by the IRWindowsTM software to analyze performance.

Model 13495 is one of a series of turn-key test systems offered by Santa Barbara Infrared. The system is designed for laboratory and production characterization and testing of modern EO instruments including thermal imagers, day sights, image intensified sensors, and direct-view optical systems. Optional modules for testing of laser rangefinders, designators, illuminators and spot trackers can be added for complete testing of currently fielded military multi-sensor pods and gimbals. Testing is automated, using the SBIR IRWindows™ system control and test platform. The Model 13495 includes an all-reflective broadband collimator, target wheel, filter wheel, range simulation stage, differential blackbody, Vis/NIR/SWIR source, and IRWindows™ . An AZ/EL stage assembly mount that interfaces to TPS fixtures for each UUT is mounted in front of the collimator, locating the UUT in collimated space. A CCD camera mounts behind the UUT and is used to view the display in the eyepiece of the UUT. Images from the CCD camera are utilized by the IRWindowsTM software to analyze performance.

The 13383 test bench system is configured specifically for characterizing the performance of IR and visible sensors and performing multi-sensor boresighting (IR to Visible to Laser). The design of the test bench is similar to many other test systems that SBIR has manufactured. The test bench includes a broadband collimator, precision differential blackbody, uniform large area visible source, 16 position motorized target wheel and manual micrometer driven range simulation platform.

The Model 13386 is designed to support high accuracy co-boresight measurement and performance of Visible, IR and Laser sub-systems mounted on a common platform. The 13386 is a fully integrated test system that includes a 12” clear aperture, 60” Newtonian collimator, camera based boresight module, differential blackbody with visible illuminator, visible source, target wheel and an adjustable focus/range platform. The NIR camera that is included in the boresight module also functions as a laser beam profiler to support laser spatial measurements.

Please contact the SBIR sales team at (805) 965-3669 or sales@sbir.com for applications engineering assistance or specific test needs.

Information subject to change without notice.