The 4100 High Temperature Cavity Blackbody operates from 50°C to 1000°C absolute temperature. It is built around an innovative cavity design that significantly improves both uniformity and slew rate of the blackbody system while simultaneously improving test accuracy and reducing test times.

The 4100 also incorporates the many advantages found across SBIR’s entire blackbody product line including: more stable and accurate temperature control, quick and easy blackbody interchangeability, non-critical cabling, multi-function controller, high immunity to EMI, ease of calibration and easy integration into a larger test system. The 4100 High Temperature Cavity Blackbody is an ideal choice for applications where high temperature and high performance are a requirement.

Superior Uniformity and Speed

Superior Uniformity and Speed

The unique cavity construction of the 4100 preserves the high emissivity of traditional cavity blackbody designs, but greatly improves the uniformity and slew rate of the system. Cooling rates are markedly faster, significantly reducing test times.

High Accuracy and Repeatability

The microprocessor-based temperature controller is designed for optimum accuracy and stability. A high resolution enhanced PID temperature servo provides zero drift and low jitter control of the emitting surface’s temperature.

Ease of Calibration

Calibration is fast and easy. All adjustments can be made directly from the front panel or through the remote interface. Calibration points are independent of each other, allowing the user to touch up a single calibration point.

Built in Test (BIT)

An extensive BIT assures that the blackbody is functioning properly during use. BIT is automatically invoked on power up and a continuous background (transparent to the user) BIT is performed during operation.

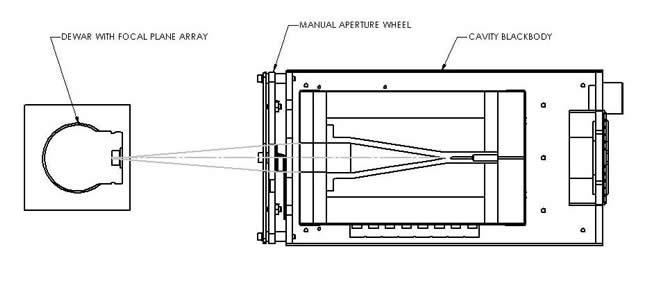

Aperture Wheel

An eight position, manual aperture wheel is included with the 4100 blackbody allowing quick and easy selection of limiting apertures and targets. Apertures are not included with the system. A large variety of pinhole apertures and slit targets are available to order.

Option G- IEEE Std. 488 Interface (GPIB)

Option G- IEEE Std. 488 Interface (GPIB)

The thorough implementation of the ANSI/IEEE Std. 488.1-1987 allows computer control of all blackbody functions, calibration, and optional features such as target wheels and illuminators. (Option G)

Option S- RS-232 Serial Interface

An optional serial interface provides computer control of all blackbody, calibration, illuminator and target wheel functions. (Option S)

Option E- Electro-Mechanics Package

Includes variable frequency chopper, motorized 12-position aperture wheel, motorized 8-position filter wheel and shutter. Read below for more information.

Aperture and Filter Wheels

A motorized aperture and filter wheel replace the manual aperture wheel from the standard configuration, enabling multiple apertures or filters to be rapidly and precisely positioned in front of the blackbody. Maximum aperture thickness for purchased filters from third party vendors should be less than or equal to 0.300″. Selection can be made from the front panel of the controller or via the optional remote interface (IEEE 488 or RS-232).

Modulator

A mechanical chopper can be used to modulate the blackbody radiation. Dynamic range of the chopper is 1000:1. A variety of blade sizes and speeds are available. The modulator can be controlled from the front panel or through the remote interface.

Rack Mounting

The blackbody controller is designed for bench-top or standard 19 inch rack use. Rack mount ears are included with the instrument. A rack slide kit is also available.

Handheld Remote Panel

An optional remote control is available. All instrument front panel functions can be accessed using this handheld unit. It is connected to the temperature controller with a 10 foot cable.

Click on the below link to view a PDF outline drawing:

Click on the below link to view a PDF outline drawing:

4100 High Cavity Blackbody

| Available Sizes | 1” Diameter Cavity |

| Temperature Range | 50ºC to 1000ºC Absolute |

| Emissivity | 0.98, 2µ to 14µ |

| Display resolution | 0.10ºC |

| Setpoint resolution | 0.10ºC |

| Stability1 | ± 0.30ºC short term, ±0.50ºC long term |

| Total System Uncertainty | ±3.5ºC or 0.5%, whichever is greater |

| Slew Rate (Approximate Heating Rate 100ºC to 1000ºC) | <60 minutes |

| Slew Rate (Approximate Cooling Rate) 1000ºC to 100ºC) | <85 minutes |

| Ready Indicator | within ±0.50ºC of setpoint |

| Line Voltage | Selectable 100 / 120 / 220 / 240 V, 50 – 60 Hz |

| Max. Power Usage | 1760w |

| Approximate Blackbody Weight | 15 lbs. |

| Approximate Controller Weight | 21 lbs. |

Notes: 1. Short term is defined as less than one hour and long term is over 1 hour.

* Specifications subject to change without prior notice

See PDF Datasheet

Loading...

Loading...

4100 Series Blackbody 3D models for download:

4100 Series Blackbody 3D models for download:

4100 CAVITY BLACKBODY ZIP

4100 CAVITY WITH ELECTRO-MECHANICS PACKAGE ZIP

MANUAL APERTURE WHEEL 8 POSITION ZIP

Order Information:

SBIR’s cavity blackbody systems are classified based on six different features that a customer can select. They are blackbody model number, communication options, country input voltage, power cable code, temperature range and cable length. For example, a 1″ Model 4100 system with Option G, 115/60Hz with US power cable, temperature range of 50°C to 1000°C and a cable length of 10 feet has the following part number: 4100G-120K-GG-10

• 1″ Cavity Blackbody: 4100

• Communications Options:

E-Electro-Mechanics Package Option (Option E)

G- IEEE-488 Interface GPIB (Cannot have both G and S simultaneously)

S- RS-232 (Cannot have both S and G simultaneously)

W- Target Wheel Communication (Please note the Target Wheel Model Number Required)

• Country Input voltage:

100

120

220

240

• Power Cable Code: (unique to the 4000 and 4100s series)

J – Japan

K – US

A – Ger., Neth., Swed.

C – China

F – France

I – Italy

D – UK

• Temperature Range:

GG = 50° to 1000° Absolute

• Cable Length (in feet)

10 feet (standard length)

customized length

Please contact the SBIR sales team at (805) 965-3669 or at sales@sbir.com to ensure the proper part number and to receive a quotation.

Information subject to change without notice.